We provide various brands and models of mold steel, processing, and one-stop customization services.

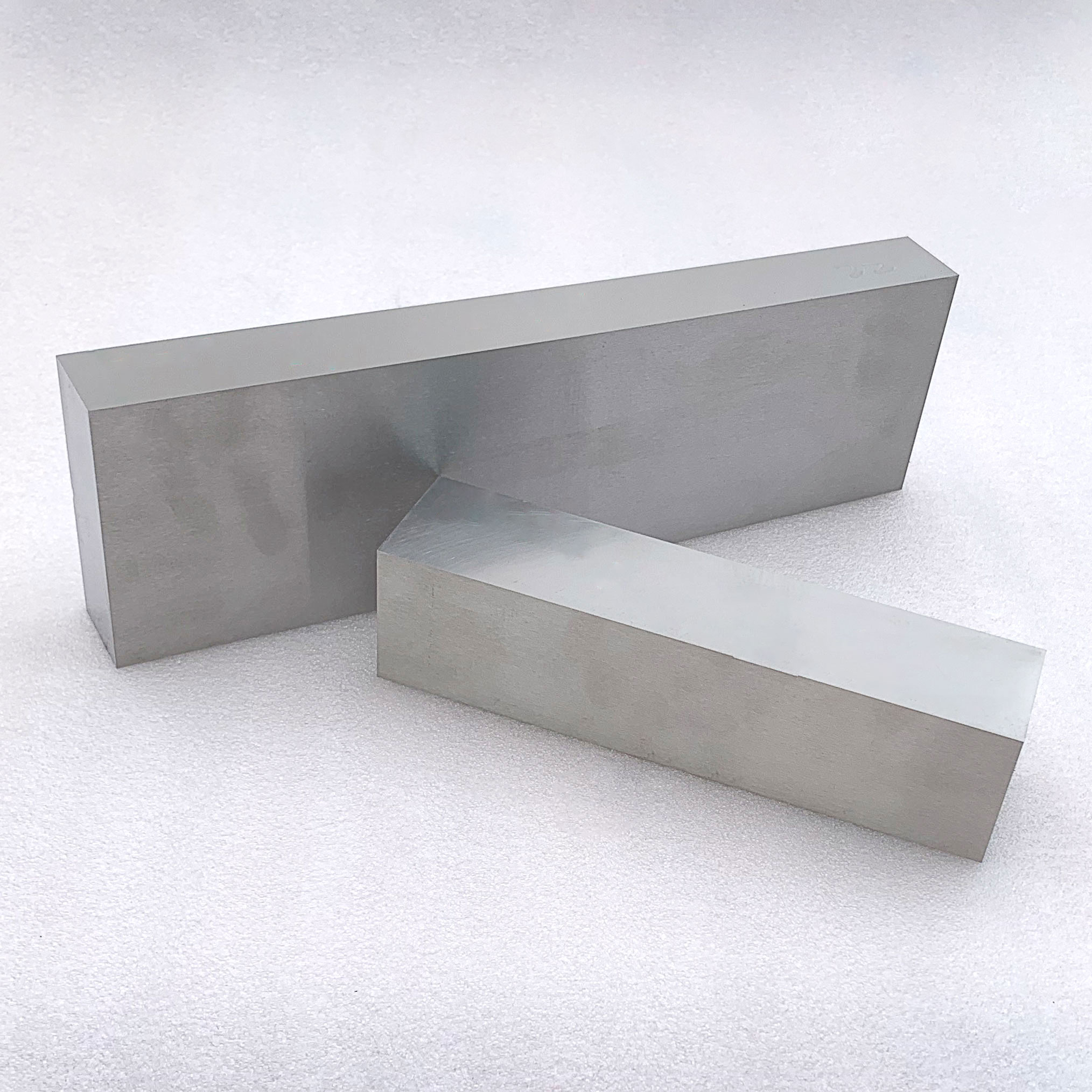

S50C die steel is a kind of high-quality carbon structural steel, it is carbon as the main strengthening element of steel, this steel through reasonable processing and heat treatment, can obtain better strength, hardness, wear resistance and certain toughness, suitable for manufacturing all kinds of mold and mechanical parts.

1、Good mechanical properties

2、Excellent machinability

3、Good wear resistance

4、Good plasticity and toughness

5、Stable dimensional accuracy

c

0.47%-0.53%

Mn

0.60%-0.90%

Si

0.15%-0.35%

P

≤0.030%

S

≤0.035%

Annealed delivery to meet user requirements

mould of plastics,stamping mould,machine part,Jigs and measuring tools,Die insert, etc

1、 Annealing: the steel is heated to 800-850 °C, held for a period of time and then slowly cooled (usually with the furnace cooling) to eliminate internal stress, improve cutting performance, and prepare the organization for subsequent heat treatment.

2.、Quenching: heating to 820-860 °C, and then quickly cooling in oil.

3、 Tempering: tempering treatment in time after quenching, tempering temperature is generally 550-650 °C, according to specific needs to choose the appropriate tempering temperature and time, in order to obtain the required balance of hardness and toughness.

Customized On Demand

Mold steels of different sizes and thicknesses can be customized according to customer needs, with an accuracy of up to 0-0.05mm. As long as there is demand, we can meet it.

Minimum Order Of 1 Piece

We can provide ordering service with a minimum of 1 piece. We will not not do it because the quantity is small, nor will we cut corners because the quantity is large. We are a strong manufacturer with guaranteed quality.

Complete Categories

The mold steels are available in many models and can be quickly stocked. The production department works 24 hours a day and will be shipped the next day under normal circumstances, saving you time and cost.

01

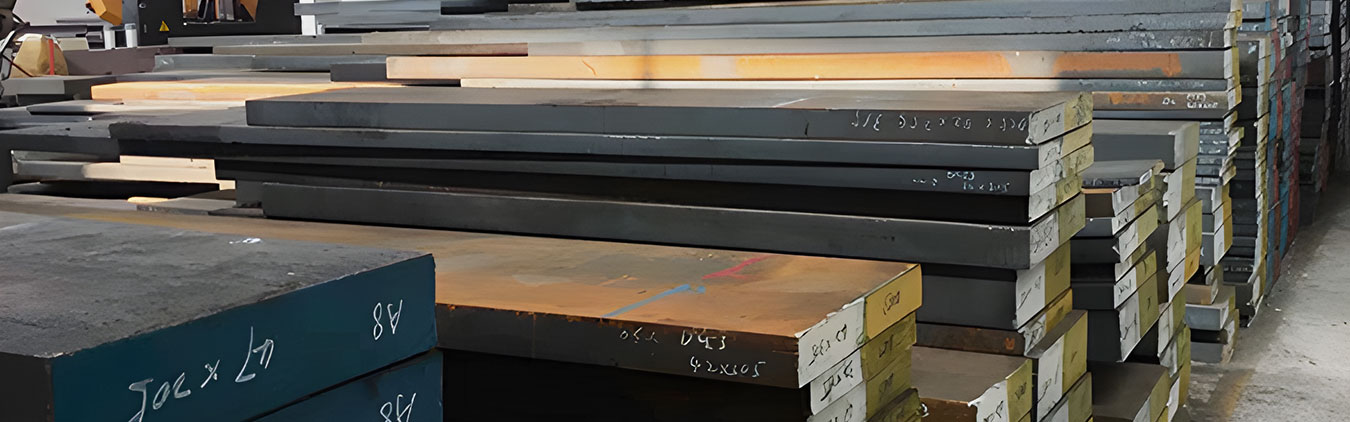

Large Steel Cutting Workshop

3000㎡ meters mold steel processing workshop

17 years of industry experience, 25 processing equipment with a monthly average production capacity of 100 tons, supporting customized orders starting from one piece

02

Delivery Speed

Longshi mold steel processing department works 24 hours a day

Under normal circumstances, the goods are shipped the next day. The delivery rate is 100% within 3 days nationwide. Door-to-door delivery is available 24 hours in Dongguan.

03

Strictly Control Quality

Complete 8 testing equipment across the entire line before shipment.

Material proof can be provided, and the accuracy can be controlled within 0-0.05MM. The light plate can be controlled within 0-0.5MM.

04

Attentive Service

Longshi Mold solemnly promises that if the product has quality problems, it can be returned or exchanged free of charge.

Full-line logistics tracking, more peace of mind; dedicated tracking before, during, and after sales to ensure timely resolution of customer after-sales problems, so you have no worries

05

Spot Inventory

Stable and sufficient inventory of mold steel raw materials

The company has its inventory. We have sufficient inventory all year round. Please feel free to place your order.

06

One-Stop Customized Processing

The company is equipped with complete mechanical processing equipment

Undertake from rough processing-rough processing-finishing-deep processing-one-stop service

07

Stable Quality

The company has established long-term and stable strategic partnerships with large-scale, high-quality mold steel companies such as Fushun Tiangong, Changgang, and Baosteel!

08

Fast Logistics

Established long-term cooperative relationships with several logistics companies to complete logistics and distribution on schedule. Goods can arrive globally in 5-10 days, and logistics and distribution are completed on schedule.

Copyright © 2023 :Dongguan Longshi Mold Steel Co., Ltd