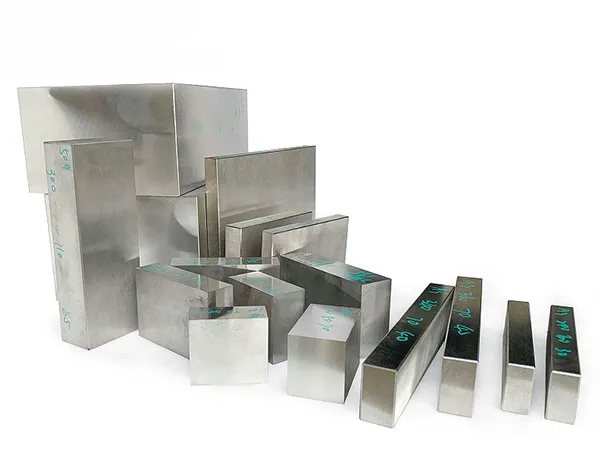

When corrosion resistance is critical, the first choice is S136 mold steel. This is a high-chromium stainless mold steel with a chromium content of up to 13%, offering excellent resistance to corrosion. In humid environments or when in contact with corrosive plastic materials, it can effectively prevent mold rusting and corrosion, ensuring mold precision and surface quality.

In addition, 2316 mold steel also provides outstanding corrosion resistance, along with good polishing and machining performance. After heat treatment, it achieves a hardness of HRC31–35, making it suitable for manufacturing plastic molds that require both high corrosion resistance and superior surface quality.