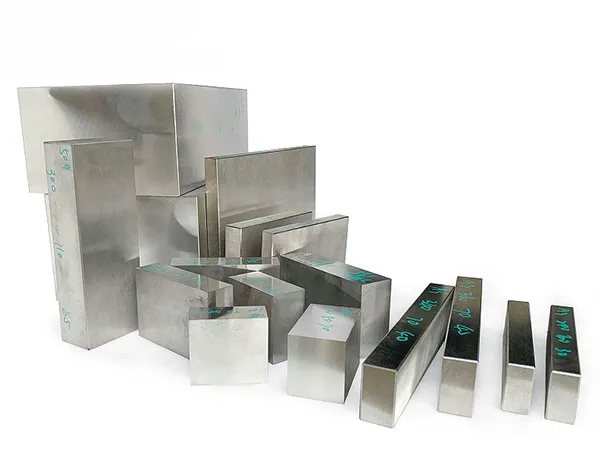

Preparing injection mold steel involves determining the steel grade, specifications, and quantities. Based on the mold design drawings, calculate the required dimensions and weight of each part, taking into account machining allowances — generally leaving 3–5 mm allowance on each side.

Choose an appropriate steel grade: for molds producing general plastic products, options include P20 mold steel or 718 mold steel; for applications requiring corrosion resistance, choose S136 mold steel; for high-precision, high-gloss molds, opt for NAK80 mold steel.

At the same time, prepare the material quality certificates and inspection reports to ensure that the steel meets the required standards.