NAK80 is commonly used for high-gloss and A-surface appearance molds, but its performance can vary significantly depending on steel quality. Based on project experience from the moldsteells team, many appearance defects are not caused by processing or polishing, but by overlooked issues in the steel itself.

This article outlines six key technical points to check when selecting NAK80, helping reduce A-surface appearance risks before mold manufacturing begins.

Where NAK80 Is Typically Used for Appearance-Part Molds

- Mobile phone housings, 3C product housings, high-gloss cosmetic appearance parts for electronic devices

- Home-appliance panels and appearance panels (e.g., LCD TV bezels), high-end exported home-appliance appearance parts (including Europe-bound high-end products)

- Automotive panels and interior trim panels (including piano-black panels), interior A-surface parts, OEM ABS interior trim parts, automotive appearance parts, high-gloss interior appearance parts

- High-end cosmetic packaging (PP), mirror-finish cosmetic packaging parts, cosmetic housings, acrylic cosmetic housings, luxury packaging / premium packaging appearance parts

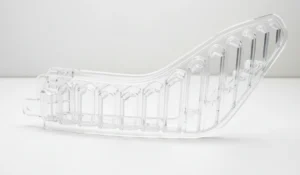

- Transparent ABS appearance parts, transparent PC appearance parts, transparent parts (PC+ABS high-gloss housings), transparent housings for medical devices, optical lens products

- Food-contact PET products, thin-wall PP products, parts molded under high-pressure injection conditions

- Appearance parts exported to Europe/USA, housings for exported medical products

What to Watch Out For (6 Key Points)

Before purchasing NAK80 steel, it helps to understand the six issue categories below. If you check these 6 points during sourcing, you can directly avoid “A-surface appearance failures” and reduce the risk of cosmetic rejection.

1) Cleanliness / Inclusions (Black Spots, Bright White Specks, Pinholes)

Black Spots / Oxide Inclusion Issues

Potential defects caused:

- Appearance: Pits and black spot marks on the product surface. On PC mirror-finish parts (e.g., home-appliance high-gloss panels), bright spots and pinholes may appear at corresponding positions. On transparent ABS appearance parts, “fisheye” patterns can occur, failing the “100% transparent, flawless” requirement. Overall, the mirror’s appearance degrades, and customers may directly judge it as appearance NG.

- Function/assembly: Thin-wall PP parts are more sensitive and may show periodic short-shot / insufficient fill (especially if the black-spot location corresponds to the thinnest wall area). In food-contact / high-temperature scenarios (e.g., PET applications), black-spot substances may precipitate or migrate, triggering compliance risks (e.g., customer audits based on food-contact regulations).

Bright White Specks (White Shiny Spots)

High-risk products:

- High-gloss / mirror-finish appearance parts (and corresponding high-polish molds)

- Optical lens products (lens molds)

- Automotive appearance parts (strict gloss requirements)

- Products molded under high-pressure injection conditions (more sensitive)

Potential defects caused:

- Appearance: During mirror polishing, bright specks often cannot be fully removed. At the end, the cavity surface may show pinholes/spots/micro-pits. On molded parts, this becomes obvious cosmetic defects and may stack with gloss inconsistency and weld lines. For optical lenses, it can be magnified into direct optical defects.

- Function/assembly: Under high-pressure injection, the bright-speck area is more prone to stress concentration. Experienced technicians report possible cracking and early failure risks, affecting stable mass production and lot-to-lot consistency.

Pinhole Issues

High-risk products: High-gloss / A-grade surface parts (ABS, electronic housings), automotive panels / interior panels (including piano-black), home-appliance panels / high-gloss phone cases, cosmetic housings, transparent PC appearance parts (transparent parts are most sensitive).

Potential defects caused:

- Appearance: Irregular micro-dents / pinhole impressions / “orange-peel-like” pitting. On high-gloss parts, obvious “pinhole marks” appear as local dark spots + uneven gloss. Transparent PC parts may show reflective bright points (e.g., a “bright-point defect”), and customers often judge the appearance as NG. Cosmetic housings commonly show “star-like” tiny pits.

- Function/assembly: For automotive appearance parts, pinhole locations can lead to poor coating adhesion in painting / plating processes, or the local depression remains visible after coating, impacting assembly appearance consistency.

Oxide Inclusion Issues

High-risk products: High-gloss / A-grade appearance parts (ABS, 3C housings, home-appliance panels), automotive interior appearance parts, mirror-finish cosmetic packaging parts, transparent PC appearance parts.

Potential defects caused:

- Appearance: Mirror polishing on the mold side can produce pitting / micro-pits, making it “unable to polish bright.” On the molded part, this results in tiny pinholes/black spots, bright-point defects, drag marks, and haze-like areas (locally inconsistent reflections). Transparent PC may also show iridescence/color streaks, and customers often judge it as “low-grade / appearance NG.”

- Function/assembly: Oxide inclusions can become defect sources of “hard spots/protrusions / pits” on the cavity surface. During production, they can scratch the melt or amplify surface scratches, leading to inconsistent appearance, yield fluctuations, and unstable mass production.

More Obvious / Poorly Dispersed Inclusions

High-risk products: Premium home-appliance high-gloss/mirror parts, automotive interior high-gloss areas, phone housings, premium cosmetic packaging, LCD TV bezels.

Potential defects caused:

- Appearance: More frequent tiny black spots, streak defects, micro-pits/bright points, along with uneven gloss and inconsistent reflection. Large flat parts like TV bezels can amplify this into obvious flow lines/flow marks, making the overall appearance look significantly lower-end.

- Function/assembly: Some automotive interior cases report that inclusions can trigger issues related to weld lines and gas traps during injection, making the appearance side more defect-prone—ultimately still judged as appearance NG.

2) Microstructure Uniformity (Uneven Brightness, “Yin-Yang” Surface, Mottling)

Uneven Brightness (Color/Shade Variation) Issues

High-risk products: Automotive interior appearance parts, home-appliance panels, acrylic cosmetic housings, PC+ABS high-gloss phone housings, transparent housings for medical devices (transparent parts).

Potential defects caused:

- Appearance: Irregular light/dark spots or strip-like shading patterns—typical “yin-yang surface.” A haze-like dark area may form, reducing overall gloss. Transparent parts often show highly noticeable concentric circular/ring-like light-dark patterns. High-gloss phone housings can magnify into bright-point-like defects, often described by customers as a “pockmarked face.”

- Function/assembly: Usually judged directly as “A-surface appearance not qualified” (especially strict for automotive interior, home-appliance panels, and medical transparent parts), even if the function is normal.

“Yin-Yang” Surface (Two Textures/Gloss Levels on the Same Face)

High-risk products: High-gloss appearance parts (ABS/PC high-gloss parts), automotive exterior parts, high-end home-appliance parts exported to Europe (more sensitive to gloss and color difference).

Potential defects caused:

- Appearance: Clear gloss zoning on the same surface (typically “half bright, half dark”), with dark spots and light/dark stripes. More visible at specific angles. Export home-appliance parts often show as color-difference surfaces that “cannot be pressed down even by polishing/process,” directly lowering the appearance grade.

- Function/assembly: Usually judged appearance NG directly (even if functional), especially strict for high-gloss PC, automotive exterior parts, and export parts.

Mottling / Patterned Surface (Haze, Water-Ripple, Blotchy Patches)

High-risk products: Home-appliance panels, automotive interior appearance parts (ABS parts with gloss targets), high-gloss phone housings (PC+ABS), mirror-finish cosmetic packaging parts.

Potential defects caused:

- Appearance: Obvious shade difference / light-dark mottling. High-gloss parts appear to lack the mirror finish, as if “covered by a fog layer.” It may also show water ripples (periodic waves) and local cloud-like mottling, giving the overall appearance a noticeably lower-end look. Automotive interior parts often fail top-tier appearance standards due to inconsistent gloss.

- Function/assembly: Appearance parts are typically judged as A-surface unqualified directly (especially strict for home-appliance panels, automotive interior, high-gloss phone housings, cosmetic packaging), even if the function is normal.

Inconsistent Polishing (Local Areas Cannot Be Polished Bright / Local Fogging)

High-risk products: Automotive exterior parts, high-gloss / mirror-finish appearance parts, phone housings, luxury/premium packaging appearance parts, appearance parts exported to Europe/USA (high mirror-grade requirements).

Potential defects caused:

- Appearance: Insufficient gloss, local fogging with pitting; the overall look becomes “gray and not clean,” and the mirror effect cannot be achieved.

- Function/assembly: Usually blocked by appearance-grade requirements (stricter for premium/export). Even if functional, it is considered an appearance NG, slowing delivery.

3) Hardness Consistency (Hard/Soft Spots, Sudden Machining Resistance Changes, Tool Wear Differences)

Hard Spots

High-risk products: High-gloss / mirror-finish appearance parts, automotive interior panels, premium home-appliance housings, cosmetic housings, phone housings.

Potential defects caused:

- Appearance: Mirror polishing easily becomes “locally cannot be polished bright / cannot reach mirror finish,” and is amplified on parts as bright points, scratches, irregular pits/indentations, micro-bumps, and uneven gloss (most obvious in high-gloss areas).

- Function/assembly: Hard-spot areas more easily cause abnormal demolding resistance, leading to drag marks/scuffing; appearance parts are often judged NG directly.

Soft Spots / Low-Hardness Areas

High-risk products: Appearance parts (especially high-gloss/mirror parts), automotive exterior parts / automotive interior A-surface, home-appliance appearance panels.

Potential defects caused:

- Appearance: Difficult to achieve cavity surface finish. On parts: sink marks, pressure marks, dents, orange peel, insufficient gloss, and more prone to drag marks/scratches and weld lines (high-gloss parts are more sensitive).

- Function / assembly: Poorer dimensional stability, larger lot-to-lot variation, tighter tolerances become harder to control.

- Rework / scrap risk: Soft-spot areas wear earlier, making surface quality increasingly unstable; repair frequency rises.

Sudden Changes in Machining Resistance

High-risk products: High-gloss appearance parts (mirror A-surface), automotive interior high-gloss parts/panels, home-appliance high-gloss panels, phone housings / 3C housings, transparent housings (medical/3C), cosmetic packaging appearance parts.

Potential defects caused:

- Appearance: The mold side is prone to chatter marks/tool marks, step errors, scratches, uneven gloss (light/dark patches/yin-yang surface), haze/orange peel. On the molded part, this is amplified into “one area bright, one area dark,” ripples/optical distortion, obvious surface defects, and a more prominent parting line.

- Function/assembly: Dimensional variation increases; flatness can drift from ≤0.001 mm requirements to around 0.008 mm, directly impacting assembly gaps, step/flushness, sealing/fit, and appearance seam consistency.

- Rework/scrap risk: Resistance fluctuation often comes with abnormal tool wear/chipping, reducing finishing stability and triggering repeated mold corrections, re-polishing, re-machining, multi-lot scrap, delivery delays, and contract penalties/claims risk.

Tool Wear Differences (Caused by Hardness Non-Uniformity)

Local hardness/microstructure non-uniformity (hard spots, soft spots, inclusions/carbide segregation) → cutting force and cutting temperature fluctuate → uneven edge wear/chipping, frequent tool changes, tool-joining marks/cutter marks, surface quality and dimensional stability fluctuations → lower machining efficiency, higher cost, and delayed delivery.

4) Porosity / Voids / Blowholes / Sand Holes

Looseness (Non-Dense Microstructure)

If NAK80 has looseness (non-dense structure / micro-voids), appearance molds can develop local pressure and heat-dissipation non-uniformity during polishing and molding. Eventually, defects are expressed as pinholes/bubbles/pits, sink dents, inconsistent gloss/color difference, and more obvious weld lines.

Blowholes / Pinholes (Point-Like Cavities)

If NAK80 has blowholes/pinholes, mirror polishing on high-gloss/mirror surfaces will form pits and pitting, black spots/bright points, local fogging, and uneven gloss. On transparent parts or piano-black surfaces, these defects are further magnified, leading to direct appearance failure and extremely high rework/scrap risk.

Sand Holes (Localized Pits / Pockmarks)

Once NAK80 cavities have sand holes (localized small pits), injection-molded appearance parts will replicate dents/pits and pockmarks at corresponding positions (pinhole-like point defects, even periodic pockmarks). This is especially obvious on high-gloss/mirror surfaces and commonly results in appearance inspection failure, full-lot rework, or scrap.

5) Cracks / Micro-Cracks (Linear White Lines Extending Along the Machining Direction)

Crack Issues

Once a NAK80 mold develops cracks, the crack morphology can be “copied” onto appearance parts, commonly showing as strip-like dents/periodic streaks, uneven gloss (brightness difference/color difference), edge flash/burrs. Cracked areas may also generate metal debris, causing black spots. On transparent parts, it can lead to silver streaks, bubbles, reduced transmittance, and appearance rejection.

Linear White Lines Extending Along the Machining Direction

Linear white lines extending along the machining direction can appear on appearance parts as white streak defects, together with surface unevenness and uneven gloss (brightness difference). High-gloss parts are especially sensitive. In severe cases, customers may reject shipments, and defect rates increase.

6) EDM and Weld-Repair Consistency Risks (Dark EDM Areas, Inconsistent Weld-Repair Zones)

Darkening in EDM Areas

Darkened EDM areas on a NAK80 mold can show on product appearance as local darkening/dark patches on high-gloss surfaces, overall uneven gloss, and color difference (bright/dark inconsistency on the same surface). At certain angles, a whitish haze-like trace or stripe may be visible, and the texture/mirror effect becomes non-uniform. Severe cases can also bring micro-pits/pockmarks. For transparent parts, it is more easily magnified into bright-point defects and optical distortion, leading to reduced transmittance and a failed appearance inspection, with a higher risk of rework/rejection.

Inconsistent Weld-Repair Areas

Inconsistent weld-repair zones on a NAK80 mold can form a “locally different patch” on the product—typically, obvious gloss differences, bright or dark patches, color differences, ripple patterns / repair-boundary marks. Weld-repair areas are also more likely to have sink marks and weld lines. For transparent parts, this can manifest as optical distortion and reduced transmittance, making it difficult to pass A-class appearance acceptance and increasing the risk of rework/rejection.

Conclusion

For A-surface appearance molds, NAK80 selection is not just about the grade name—it’s about consistency. If you verify these six points (cleanliness, structure uniformity, hardness consistency, internal defects, crack risk, and EDM/weld consistency) before purchase, most high-gloss appearance failures can be avoided before the mold is built.