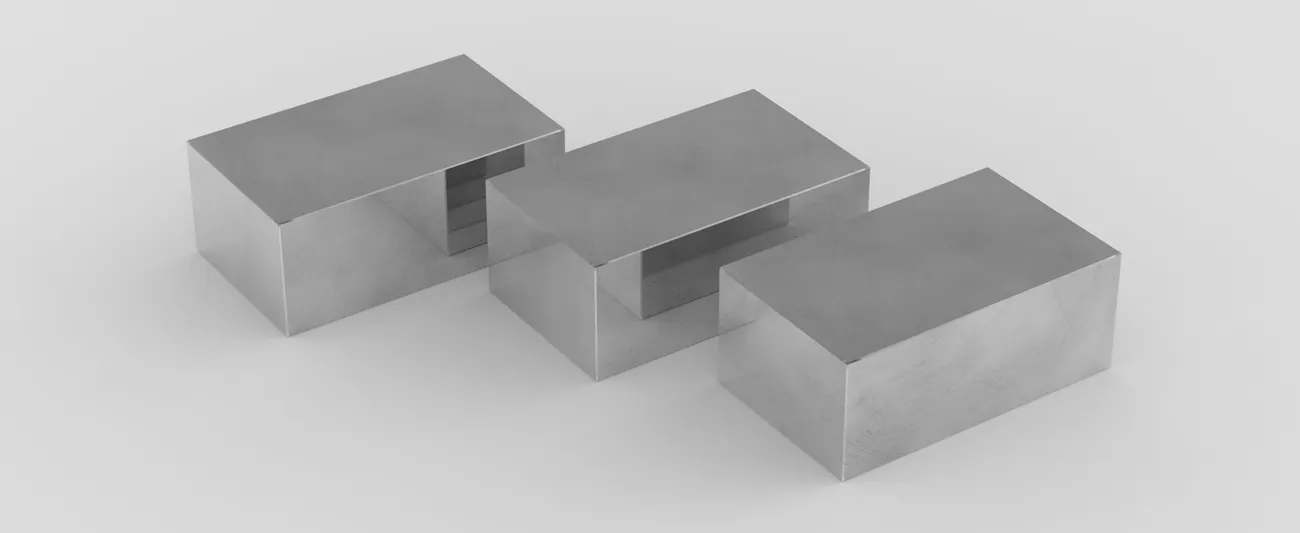

What Is H13 Tool Steel?

H13 is regarded as an “all-round performer” in the field of hot work tool steels. Through a multi-alloy system of carbon, chromium, molybdenum, and vanadium, it achieves an optimal balance between hardness, toughness, and thermal stability. It is widely used in aluminum die casting, hot forging, and other core industrial applications, with mold service life exceeding 100,000 cycles.

As a professional mold steel processing team, Moldsteells summarizes key properties and application guidelines of H13 based on our practical experience and material data, helping you select materials accurately and improve machining efficiency.

Main Characteristics of H13 Tool Steel

- Balanced Strength and Toughness: Quenched hardness HRC 42–50, impact toughness 15–35 J/cm², tensile strength around 1000 MPa at 600°C.

- Excellent Hardenability and Thermal Stability: Synergistic effect of Cr/Mo/V ensures through-hardening and stable tempering hardness.

- High Thermal Fatigue and Oxidation Resistance: Dense oxide film formed by Cr/Si resists cracking under thermal cycling.

- Good Machinability: Annealed hardness ≤229 HBW, suitable for mass production.

- Clear Performance Limitations: Insufficient cold-work hardness, poor polishability, and weak corrosion resistance.

Chemical Composition of H13 (ASTM A681)

| Element | Range (wt%) | Function |

|---|---|---|

| C | 0.32–0.45 | Ensures hardness and wear resistance |

| Cr | 4.75–5.50 | Improves hardenability and oxidation resistance |

| Mo | 1.10–1.75 | Enhances tempering stability |

| V | 0.80–1.20 | Refines grains and improves wear resistance |

| Si | 0.80–1.20 | Improves thermal fatigue resistance |

| Mn | 0.20–0.50 | Assists hardenability |

| P | ≤0.030 | Impurity control |

| S | ≤0.030 | Impurity, affects toughness |

| Ni+Cu | ≤0.75 | Residual element control |

Physical Properties of H13

| Property | Value | Unit | Remarks |

|---|---|---|---|

| Density | 7.85 | g/cm³ | ASTM A681 |

| Elastic Modulus | 210 | GPa | Temperature dependent |

| Thermal Expansion | 9.1–13.5 | ×10⁻⁶/°C | 20–700°C |

| Thermal Conductivity | 28.8–32.2 | W/(m·K) | 25–650°C |

| Ac₁ | 860 | °C | Austenite start |

| Ms | 340 | °C | Martensite start |

Mechanical Properties of H13

| Category | Parameter | Value | Unit | Condition |

|---|---|---|---|---|

| Tensile | Tensile Strength | 1800–2200 | MPa | Q&T, RT |

| Yield Strength | 1500–1800 | MPa | Q&T, RT | |

| Elongation | ≥8 | % | Q&T, RT | |

| Compression | Compressive Strength | ≥2500 | MPa | Q&T, RT |

| Impact | Room Temp Impact | 15–35 | J/cm² | 20°C |

| Low Temp Impact | ≥20 | J/cm² | -40°C | |

| Hardness | Annealed | ≤229 | HBW | RT |

| Q&T | 42–50 | HRC | RT | |

| High Temp | 600°C Tensile | ~1000 | MPa | 600°C |

| 600°C Yield | ~850 | MPa | 600°C | |

| 600°C Hardness | 35–38 | HRC | 600°C | |

| Fatigue | Rotating Bending Limit | 600–800 | MPa | RT |

Typical Applications of H13 Tool Steel

- Aluminum and magnesium die casting molds

- Automotive crankshaft and connecting rod forging dies

- Aluminum extrusion dies

- High-temperature plastic molds

- Precision hot forming molds

- Cost-optimized composite molds

Non-Recommended Applications

- Cold forging and cold heading dies

- Ultra-high hardness molds (HRC ≥58)

- Mirror-finish plastic molds

- Corrosive environments (PVC, sulfur/chlorine media)

- Long-term service above 650°C

- Low-volume economical molds

H13 Selection Reference Table

| Category | Recommended | Not Recommended |

|---|---|---|

| Hot Work | Die casting, hot forging, extrusion, hot stamping | Long-term >650°C, ceramic/glass forming |

| Plastic Mold | GF reinforced plastics, high-temp plastics | Mirror polish molds, PVC molds |

| Cold Work | Low-load cold stamping | High-strength cold extrusion, deep drawing |

| Special | Mass production, thermal cycling molds | Small batch, strong corrosion, micro molds |

Recommended Cutting Tools for H13 Machining

| Stage | Tool Type | Coating | Parameters | Recommended Brands |

|---|---|---|---|---|

| Roughing | Micro-grain Carbide | AlCrN / TiSiN | 8–12% Co | Sandvik, Kennametal, ZCC, Xiamen Golden Egret |

| Semi-Finishing | Coated Carbide | TiAlN+AlCrN | 45° Helix | Kyocera, Iscar, TaeguTec |

| Finishing | CBN | None | ≥90% CBN | Element Six, Kyocera, Sumitomo |

| Mirror | PCD | None | R0.1–0.2 | Element Six, Sumitomo |

Machining Parameter Selection Guide

Cutting Speed

Annealed: 120–150 m/min

Pre-hardened: 80–120 m/min

Hardened: 50–90 m/min

Feed Rate

Roughing: 0.15–0.3 mm/r

Finishing: 0.05–0.15 mm/r

Depth of Cut

Roughing: 1–3 mm

Finishing: 0.1–0.3 mm

Spindle Speed

Φ6mm: 3000–5000 rpm

Φ10mm: 1500–3000 rpm

Φ20mm: 800–1500 rpm

Cooling

High-pressure coolant, oil mist, EP cutting oil

Tool Path

Contour milling, spiral milling, trochoidal milling

Common Problems and Solutions

1. Rapid Tool Chipping After Quenching

Use CBN tools (BN-S20), vc=80–100 m/min, oil-based coolant.

2. Chatter Marks on Cavity Surface

Use shrink-fit holders, reduce feed, increase spindle speed.

3. Chip Entanglement in Deep Cavities

Use long-neck tools, internal coolant, and peck milling.

4. Scratches in Mirror Machining

Use PCD tools, high speed, shallow depth.

5. Micro Cracks After CNC Machining

Low-temperature aging, small feed, and depth.

6. Spindle Vibration in High-Speed Milling

Avoid resonance, use balanced tools.

7. Dimensional Deviation in Mass Production

Temperature compensation and tool wear control.

8. Drill Breakage in Deep Holes

Use Co-HSS drills, peck drilling, internal cooling.

H13 Detailed Performance Data PDF Download

| Item | Details |

|---|---|

| File | h13-tool-steel-properties-machining-guide-and-applications-explained.pdf |

| Type | application/pdf |

| Size | 183 KB |

| Link | https://moldsteells.com/wp-content/uploads/2026/02/h13-tool-steel-properties-machining-guide-and-applications-explained.pdf |