The core contradiction in stamping die steel selection lies in balancing performance requirements with cost control: the steel must meet the die’s strength, wear resistance, and other service requirements, while avoiding unnecessary cost waste. In real production, companies often fall into common traps—either unthinkingly choosing high-priced imported steels that drive costs too high, or saving too aggressively by using ordinary carbon steels that cause premature die failure (such as edge chipping and cavity wear). Based on a three-dimensional framework of “performance–cost–application scenario,” this article combines practical case analysis to explain how to select the right steel scientifically. This content is compiled from Moldsteells’ practical experience in die steel selection projects.

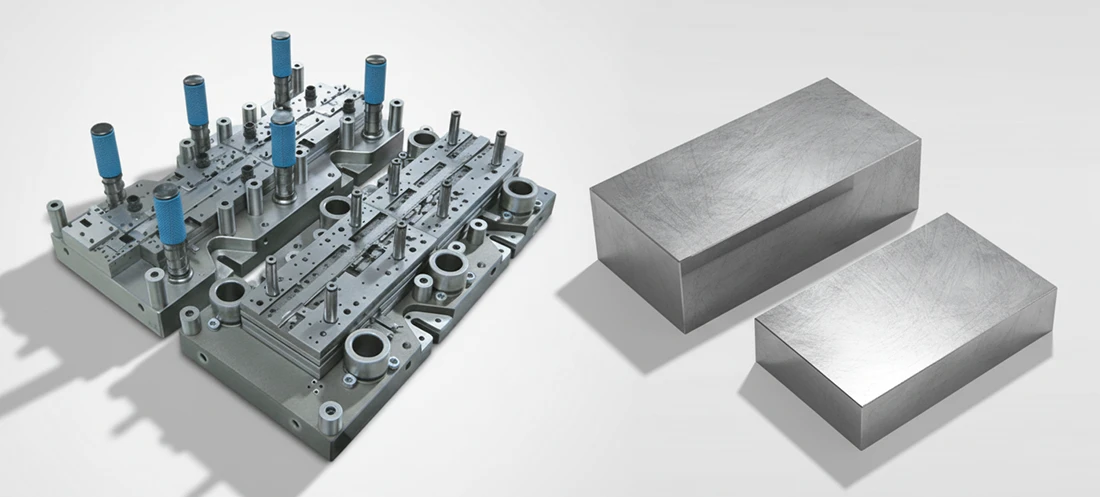

Common Stamping Die Steel Grades and Their Characteristics

Along the “performance–cost” gradient, commonly used economical die steels can be divided into the following categories to match different application needs:

- Carbon structural steels: such as 45# and 50# steels. Under conventional conditions, they are suitable for low-stress, simple-shape stamping dies (e.g., gaskets, small hardware parts). Their cost is only 50%–60% of tool steels, while meeting basic strength requirements.

- Tool steels: For simple stamping scenarios (e.g., stamping low-carbon steel sheets with thickness ≤ 3 mm), T8 and T10 tool steels can be selected, and their prices are about 30% lower than the Cr12 series (under typical market conditions). For hard-to-machine materials such as stainless steel, 9SiCr tool steel is better—it offers 40%+ improved wear resistance compared with T8, while its price is still lower than Cr12MoV.

- Cold work die steels: medium-to-high alloy steels such as Cr12 and Cr12MoV, suitable for high-stress, complex-shape stamping (e.g., deep drawing and multi-stage forming), offering a balanced combination of toughness and wear resistance.

- China-made substitute steels: LD steel (7Cr7Mo2V2Si) produced by Fushun Special Steel has better strength and toughness than Cr12 and is suitable for complex curved-surface stamping; GD steel (6CrNiSiMnMoV) produced by Fushun Special Steel has wear resistance close to high-speed steel, with a cost about 30% lower than imported SKD11, making it suitable for medium-batch precision stamping.

Key Steel Economy Comparison: Price vs Service Life

Different steels show significant differences in “purchase cost–service life,” which directly affects overall economics. Evaluation should be made from a full life-cycle perspective:

- T8/T10 vs Cr12: Under typical market conditions, T8 and T10 are about 30% cheaper than the Cr12 series, but in small-batch stamping conditions for low-carbon steel sheets with thickness ≤ 3 mm (hardness HB100–150) and stamping speed ≤ 30 strokes/min, their service life is only 1/3–1/2 that of Cr12. They are suitable for simple parts with annual output ≤ 50,000 pcs.

- Cost advantage of China-made alternatives: Under conventional conditions, Cr12 from Fushun Special Steel can replace imported D2 steel. Its composition and wear resistance are similar, while the price is reduced by about 40%, especially suitable for medium-batch stamping scenarios.

- High-speed steel vs ordinary carbon steel service life: For high-strength steel sheets with thickness 3–8 mm (hardness HB200–250) at stamping speeds of 15–25 strokes/min, high-speed steel (e.g., W6Mo5Cr4V2) has a service life 3–8 times that of ordinary carbon steel (45#). It is especially suitable for stamping high-strength steel plates (such as automotive side member steel) and can reduce die change frequency.

- Unit stamping cost quantification: Using a typical small-to-medium batch stamping case as an example (assuming identical die size and machining process), the total investment for a 45# steel die is about USD 857–1,429, with a unit cost of about USD 0.0086–0.0143 per piece; the total investment for a Cr12MoV die is about USD 1,714–2,571, with a unit cost of about USD 0.0171–0.0257 per piece. Its service life can reach 200,000–400,000 pcs, and the long-term unit cost can be reduced to about USD 0.0057–0.0086 per piece. [Supplementary calculation model]

Select Steel by Scenario: Volume, Material, and Complexity

Using the 3D scenario selection method of “annual output–stamping material–part complexity” can achieve optimal cost:

- By annual output (under conventional conditions): For easy-to-machine materials such as low-carbon steel, when annual output is below 10,000 pcs, ordinary carbon steels like 45# are more economical (lower one-time investment). For annual output of 10,000–100,000 pcs, 9SiCr and other tool steels can be selected. For over 100,000 pcs, medium-to-high alloy steels (such as Cr12MoV) are recommended to reduce unit cost by extending service life.

- By stamping material: Stainless steel stamping should focus on wear resistance. 9SiCr, with quenched hardness of HRC60–62, matches the surface work-hardening characteristics of stainless steel. For shallow-drawing dies (e.g., aluminum product lids), a combination such as “Q235 die set + 45# punch/die” can be used, significantly reducing costs compared with all-alloy dies.

- By part complexity: Apply a “graded use” strategy—use 45# for simple parts (e.g., flat punching), Cr12 for moderately complex parts (e.g., brackets with bending features), and Cr12MoV for complex parts (e.g., multi-cavity formed parts). This optimizes total die cost while ensuring service life.

Low-Cost Optimization Tips: Purchasing and Reuse

After determining the steel grade, the following practical methods can further reduce costs:

- Prioritize China-made alternatives: In conventional stamping scenarios, Cr12 from Fushun Special Steel can replace imported D2, lowering price by about 40%, while meeting performance requirements for most working conditions.

- Negotiate through bulk purchasing: Signing quarterly/annual purchasing contracts with suppliers (e.g., single purchase ≥ 5 tons) can typically reduce prices by 15%–20% compared with retail (depending on steel grade and market fluctuations).

- Old die repair and surface enhancement: After laser cladding repair on worn edges, an old die’s service life can recover to 70%+ of a new die; hard chrome plating on the surface of ordinary carbon steel dies (thickness 5–10 μm) can improve wear resistance by 50%, suitable for small-batch precision stamping.