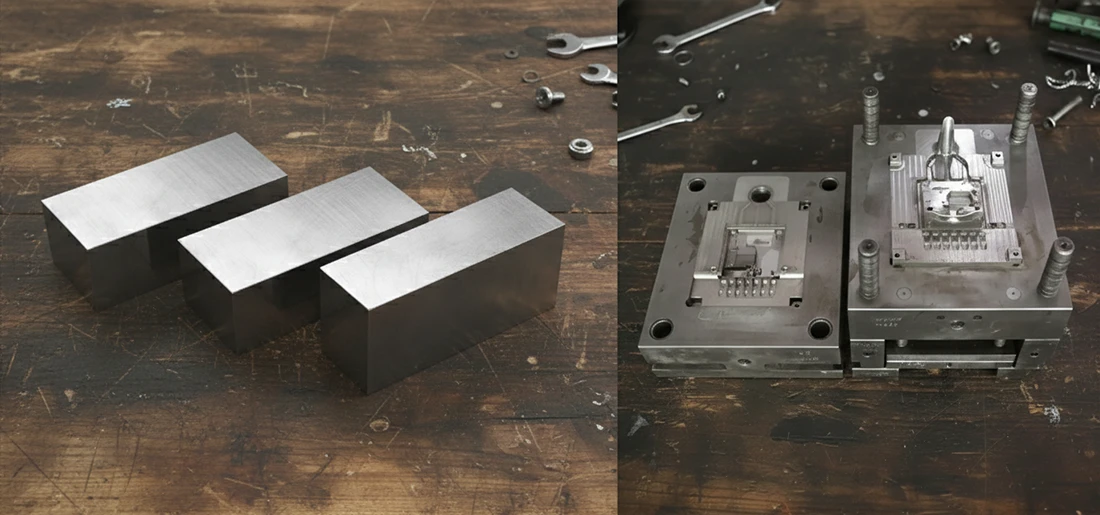

When making die casting molds, many people struggle with the same question: which steel grade is more cost-effective? You want to control costs, but you also worry the mold life will be too short, which could affect production. Some customers say directly, “I want a steel grade priced at USD 2,857–3,571 per ton, with a service life of over 50,000 shots—balancing cost and durability.” Some small workshop owners ask, “Is there a budget-friendly grade that works for small quantity orders? Preferably easy to machine—we only have conventional milling machines.” In fact, choosing the right mold steel is not about “the more expensive, the better,” but about matching the die casting material, production volume, and machining conditions. This content is compiled from Moldsteells’ practical experience in customized mold-steel projects, for your reference.

Select by Die Casting Material: Cost-Effective Grades for Aluminum Alloy vs Zinc Alloy

Die casting mold steel selection should first match the die casting material and production volume. Different materials vary significantly in temperature and pressure, so the best cost-performance steel grades also differ.

Aluminum Alloy Die Casting: Choose by Production Volume

- Small batch (annual output < 10,000 pcs): S50C can be used—for example, simple-structure, low-output molds for seasonal promotional small-appliance housings. Material cost is low, and performance is sufficient.

- Medium batch (10,000–100,000 pcs): Recommend China-made H13 (4Cr5MoSiV1). According to GB/T 1299-2014, it is designed for aluminum alloy die casting. The price is about USD 2.29–2.86/kg (about USD 2,286–2,857/ton), which is 30–40% cheaper than imported H13. Under conventional process conditions (die casting temperature 650–700°C, pressure 80–120 MPa), and with standardized heat treatment (quenching 1020–1050°C, tempering 3 times), mold life can reach 50,000+ shots.

- Large batch (> 100,000 pcs): Upgrade to higher-grade steels such as DHA1 or STAVAX to improve high-temperature fatigue resistance—for example, long-term production parts like automotive engine blocks.

Zinc Alloy Die Casting: Lower Temperature, More Economical Options

Zinc alloy die casting temperature is lower than that of aluminum alloy (about 400–450°C). The steel’s heat-resistance requirement is lower, so more cost-effective materials can be selected:

- Small batch (< 10,000 pcs): P20 or 718H pre-hardened steel—e.g., die casting toy parts with only a few thousand pieces. No follow-up heat treatment is needed, machining is convenient, and cost is 15–20% lower than H13.

- Medium batch (10,000–100,000 pcs): China-made H13 variants, with better cost performance than imported 8407, especially suitable for medium-complexity molds such as home-appliance accessories.

- When surface requirements are not high: 2344 steel is also an alternative—for example, die casting hardware tool handles, with an obvious cost advantage.

3 Cost-Effective Selection Strategies: Spend Less, Get More

Choosing the right strategy can further reduce costs. The following three methods have been proven in practice and can achieve “15–40% lower cost with no compromise in performance.”

1) Replace Imported with China-Made Alternatives: 30–40% Price Difference

For aluminum alloy die casting with an annual output under 100,000 pcs, China-made H13 equivalent steel can fully meet requirements. For example, if imported H13 is USD 4,000/ton, a China-made equivalent may be only USD 2,286–2,571/ton, reducing unit price by 30–40%. Under medium-batch aluminum die casting (10,000–100,000 pcs) and conventional conditions (650–700°C, 80–120 MPa), plus standardized heat treatment (quenching 1020–1050°C, tempering 3 times), mold life can reach 50,000+ shots, meeting small-to-medium production needs.

2) Zoned Material Selection: Reduce Overall Cost by 15–20%

Different mold areas bear different loads and wear, so there is no need to use expensive steel for the entire mold. For example, for an automotive transmission housing mold, use H13 for critical parts such as cavities and cores to ensure service life, while using 45# steel or P20 for non-critical parts (such as the mold base and guide pillars). Note that at welding joints between different steels, preheat to 200–250°C to avoid cracking. This can reduce total material cost by 15–20%.

3) Use Pre-Hardened Steel to Save Processes: Reduce Machining Cost by 20%

For small-batch production, prioritize pre-hardened steels (such as P20, 718H) with hardness already at 30–35 HRC, eliminating subsequent heat-treatment steps. Taking a zinc-alloy small-batch mold (e.g., small toy parts) as an example, using P20 instead of H13 reduces heat-treatment steps, shortens the machining cycle by 30%, and lowers total cost by 20%.

Pitfall Reminders: Avoid These 3 Common Mistakes

Choosing the wrong steel can increase costs at best, or cause premature mold failure at worst. Pay special attention to the following three mistakes.

1) Focusing Only on Unit Price and Ignoring Mold Life: It Can Cost More

A small home-appliance factory used China-made 3Cr2W8V (unit price USD 2,714/ton) to replace H13. Although the unit price was 30% lower, mold life was only 30,000 shots, while imported H13 (USD 4,000/ton) achieved 80,000 shots. Calculated by cost per shot: 3Cr2W8V is about USD 0.09/shot, while H13 is about USD 0.05/shot—the former is actually more expensive.

2) Small Workshops Choosing Hard-to-Machine Grades: Equipment Cannot Keep Up

Some small workshops purchased high-hardness, non-pre-hardened steel (such as H13 in annealed condition) but only had conventional milling machines. Machining efficiency was low, accuracy was poor, and they ultimately had to outsource machining, adding an extra 30% to costs.

3) Improper Heat Treatment on China-Made Steel: Performance Gets Discounted

An automotive parts factory purchased China-made H13 but did not strictly control quenching temperature (actual only 980°C, while the standard is 1020–1050°C), and tempered only 2 times (standard is 3 times). After 20,000 shots, the cavity showed heat-checking/cracks, and the mold life reached only 50% of the target.

Conclusion

The core of choosing cost-effective die casting mold steel is “match to your actual needs.” For aluminum alloy small-to-medium batches, prioritize China-made H13 (USD 2.29–2.86/kg, USD 2,286–2,857/ton). For zinc alloy small batches, use P20/718H (cost 15–20% lower than H13). Using China-made alternatives and zoned material selection can reduce costs by 15–40%, and pre-hardened steel saves processes.