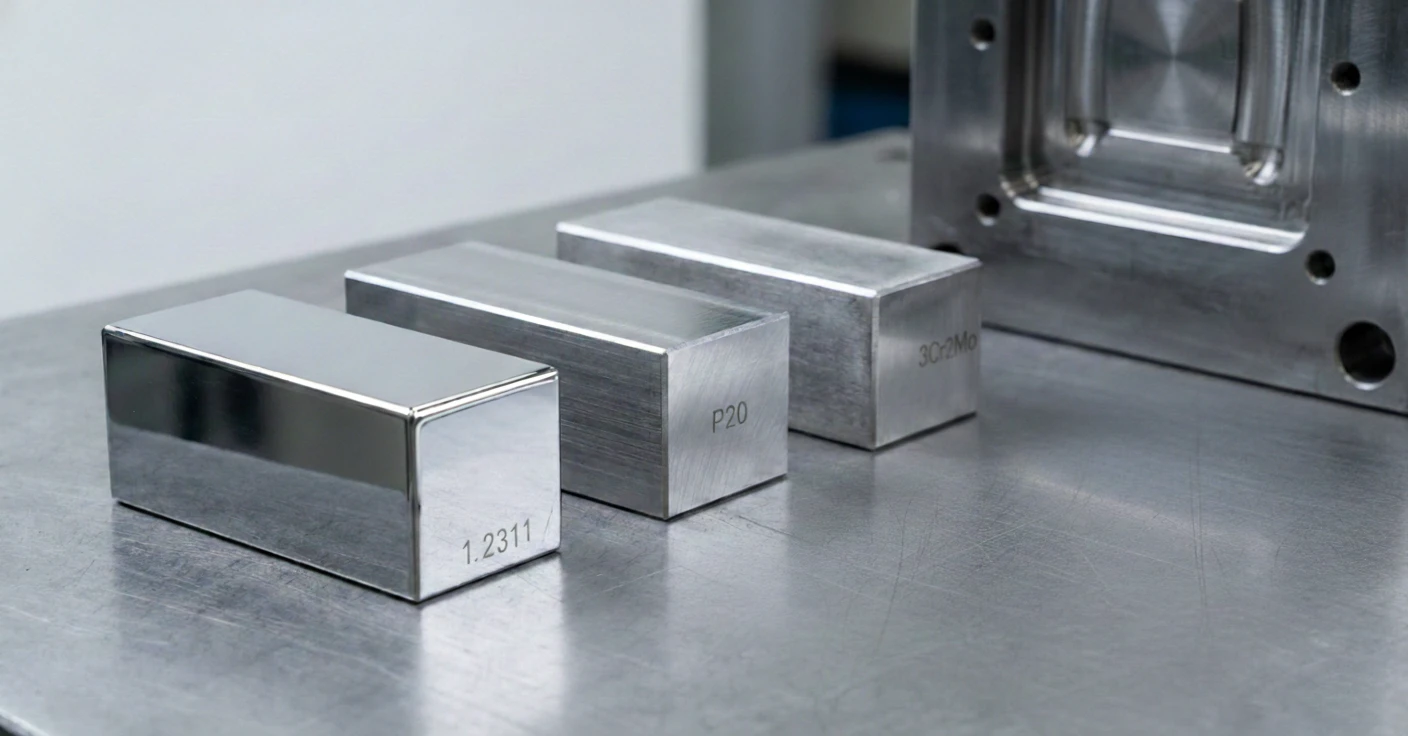

Injection-molded home appliance housings demand extremely high standards for appearance quality and mass-production stability. The choice of mold steel not only directly determines the surface finish and yield rate, but also—by affecting machining lead time and the frequency of later maintenance—ultimately determines the total life-cycle cost of the mold. The moldsteells team conducted an in-depth comparison of three commonly used pre-hardened steels in the home appliance industry: P20, 3Cr2Mo, and 1.2311, aiming to provide you with a battle-tested selection reference.

Why Compare P20, 3Cr2Mo, and 1.2311?

P20, 3Cr2Mo, and 1.2311 are often compared together because they all fall within the same performance range of “pre-hardened plastic mold steels” (equivalent/near-equivalent grades under different national standards). Their machining and application scenarios overlap heavily. As for the subtle differences, we will expand them in the parameter comparison tables below.

What Requirements Do Injection-Molded Home Appliance Housings Have?

- Appearance aesthetics: Must ensure zero sink marks and zero black spots, with color tolerance ΔE ≤ 1.5. This directly requires mold steel with very high cleanliness to support high-level polishing.

- Precision assembly: Key dimensional tolerances usually need to be controlled within ±0.2 mm. This requires excellent dimensional stability over long production runs and strong resistance to deformation.

- Structural complexity: Considering uneven wall thickness (1.5–3 mm) and heat-dissipation requirements, the mold steel needs good thermal conductivity and a uniform microstructure to prevent localized overheating that can cause part deformation.

- Adaptability to harsh environments: For overseas hot-humid or low-temperature markets, housings need UV resistance and damp-heat resistance. This requires the mold steel to have a certain level of corrosion resistance, or to perfectly match surface coating, IMD/IML, and similar processes.

- Compliance and safety: Must meet RoHS/REACH and UL94 flammability ratings. The use of flame retardants often produces acidic gases, which challenges the chemical stability of the mold surface.

Core Requirements for Mold Steel in Home Appliance Housing Injection Molds

- High-gloss polishing performance: Home appliance housings have extremely high requirements for aesthetics. The steel must be clean and low in inclusions (low S and P), and reliably achieve SPI A-2 mirror gloss. After polishing, there should be no pinholes and no orange peel.

- Hardness consistency: For large housing molds, good hardenability is required to ensure minimal hardness fluctuation from surface to core. This prevents parting line collapse during long-term mass production, and prevents mold deformation caused by non-uniform stress.

- Wear resistance and ultra-long service life: Home appliances have long product life cycles. Mold steel must have excellent resistance to erosion/impingement to ensure that under high-pressure injection for 500,000–1,000,000 molding cycles, dimensions remain accurate—especially when processing glass-fiber-filled materials where wear resistance is critical.

- Machining and maintenance cost: The material must have good CNC machinability to shorten lead time. At the same time, it must have excellent weld-repair capability, ensuring that during mold modifications or repairs, the welded area will not crack and will leave no shadow after polishing.

Comparison of Parameters for P20 / 3Cr2Mo / 1.2311

Chemical Composition Comparison

| Element Symbol | Element Name | AISI P20 (US Standard) | GB 3Cr2Mo (China Standard) | W.Nr. 1.2311 (German/European Standard) |

|---|---|---|---|---|

| C | Carbon | 0.28 – 0.40 | 0.32 – 0.45 | 0.35 – 0.45 |

| Si | Silicon | 0.20 – 0.80 | 0.20 – 0.50 | 0.20 – 0.40 |

| Mn | Manganese | 0.60 – 1.00 | 0.60 – 0.90 | 1.30 – 1.60 |

| Cr | Chromium | 1.40 – 2.00 | 1.80 – 2.10 | 1.80 – 2.10 |

| Mo | Molybdenum | 0.30 – 0.55 | 0.15 – 0.30 | 0.15 – 0.25 |

| P | Phosphorus | ≤0.030 | ≤0.030 | ≤0.035 |

| S | Sulfur | ≤0.030 | ≤0.030 | ≤0.035 |

Performance Comparison

| Comparison Dimension | AISI P20 (US) | GB 3Cr2Mo (China) | W.Nr. 1.2311 (Germany) |

|---|---|---|---|

| Pre-hardened Hardness Range | 28 – 34 HRC (general grade) | 28 – 34 HRC | 28 – 34 HRC (typical delivery average ≈ 32 HRC) |

| Microstructure Uniformity | Good. Standard density level; for large cross-sections, core hardness may drop slightly. | Relatively good. Matches mainstream injection-molding needs in China; high-quality batches show uniform core structure. | Excellent. High Mn formulation ensures outstanding hardenability and core hardness consistency for large blocks (>400 mm thick). |

| Polishing Potential | SPI B-2. Meets most home appliance appearance requirements and standard texturing needs. | SPI B-2. Good potential for fine matte texture and lower-requirement mirror polishing. | SPI B-1 / B-2. Finer structure; better gloss uniformity after polishing. |

| Machining Characteristics | Excellent machinability. Optimized Mo content makes tool wear highly stable, suitable for long-cycle milling. | Stable machinability. Suitable for common domestic machines and tooling; high overall cutting efficiency. | High stability. Although Mn is higher, modern refining enables uniform cutting torque, suitable for precision CNC machining. |

Raw Material Cost Comparison for P20 / 3Cr2Mo / 1.2311

| Steel Grade Standard | Origin / Brand Category | Reference Price Range (USD/kg) | Cost Premium Logic & Added Value |

|---|---|---|---|

| GB 3Cr2Mo | China-made standard (GB) | 2.64 – 3.21 | Best value for money: the most competitive base price, suitable for high-volume, budget-sensitive home appliance projects. |

| AISI P20 | China-made upgraded (AISI/ASTM specified) | 2.71 – 3.57 | Industry hard currency: slightly higher than GB, mainly to satisfy Western customers’ specified ASTM standard requirements. |

| AISI P20 | Made in USA (e.g., Finkl) | 5.00 – 7.14 | Brand premium: includes international freight, import duties, and ultra-high cleanliness endorsement, suitable for precision projects specifying country of origin. |

| W.Nr. 1.2311 | China-made premium (DIN/EN grade) | 3.57 – 5.00 | Performance premium: higher Mn increases smelting cost slightly; the premium shows up in core hardness consistency for large molds. |

| W.Nr. 1.2311 | Imported from Germany/Europe | 5.00 – 7.14 | Process benchmark: top European refining technology (e.g., vacuum degassing) ensures extremely low segregation rate, suitable for high-demand molds such as automotive components. |

Machining Cost & Efficiency Comparison for P20 / 3Cr2Mo / 1.2311

| Item | AISI P20 / GB 3Cr2Mo | W.Nr. 1.2311 (Germany Standard) |

|---|---|---|

| Machining Difficulty | Standard difficulty (1.0) | 20% harder than the left |

| Tool Durability | Can run 100 hours (100%) | Only 80 hours |

| Machining Time | Finish in 10 hours (1.0) | Needs 11.5 hours |

| Surface Effect | Looks good (standard) | Brighter and finer |

Polishing Performance & Risk Comparison for P20 / 3Cr2Mo / 1.2311

| Comparison Dimension | AISI P20 (US) | GB 3Cr2Mo (China) | W.Nr. 1.2311 (Germany) |

|---|---|---|---|

| Maximum Polishing Grade | SPI B-2 (Ra 0.05 μm) | SPI B-2 (Ra 0.05 μm) | SPI A-3 / B-1 (Ra 0.02 μm) |

| Typical Polishing Risks | Pinholes and pitting (Pinholes) | Orange peel (Orange Peel) | Scratches caused by hardness non-uniformity |

| Root Causes | Higher sulfur (S) content; sulfide inclusions form more easily. | Carbide segregation or obvious banded structure. | Mainly caused by heat-treatment process fluctuations. |

| Polishing Efficiency | 1.0 (baseline) | 1.15 (slightly faster) | 1.40 (very fast) |

| Recommended Applications | Texturing/etching, general appearance parts. | Fine matte texture, medium-gloss housings. | High-gloss, mirror finish, transparent plastic parts. |

Life-Cycle Total Cost Comparison for P20 / 3Cr2Mo / 1.2311

| Dimension | AISI P20 | GB 3Cr2Mo | W.Nr. 1.2311 |

|---|---|---|---|

| Base Life (cycles) | 300,000 – 500,000 | 500,000 – 800,000 | 600,000 – 1,000,000 |

| First Maintenance Threshold | Approx. 50,000 – 80,000 cycles | Approx. 80,000 – 120,000 cycles | Approx. 150,000 – 200,000 cycles |

| Common Maintenance Items | Polish restoration, weld repair for pinholes | Parting line collapse repair | Cooling channel cleaning, local nitriding |

| Difficulty of Mold Repair | Low (easy to weld) | Medium (watch segregation) | High (strict preheating required) |

| Maintenance Frequency | High | Medium | Low |

| Total Cost at 1,000,000 Cycles | Highest (includes multiple repair costs) | Medium (high value for money) | Lowest (higher per event, lower total) |

Overall Pros & Cons Summary: P20 / 3Cr2Mo / 1.2311

| Steel Grade | Positive Comments | Negative Comments |

|---|---|---|

| AISI P20 (US) | International “passport”: highest global acceptance; the “no-dispute” standard for export molds, with extremely stable composition control. | Value depression: performance sits in the middle—no obvious weaknesses but no standout strengths; brand premium makes it more expensive. |

| GB 3Cr2Mo (China) | Best value for money: can perfectly replace P20 in 80% of general molds; excellent toughness; greatly reduces initial procurement cost. | Quality fluctuation risk: many small-mill materials exist in the market; if not from major producers, hard spots or sand holes may appear and affect polishing; core hardness can soften in large sections. |

| W.Nr. 1.2311 (Germany) | Precision and stability: highest cleanliness; extremely uniform hardness in thick plates; the anchor for high-gloss mirror polishing and large precision molds. | Cold and difficult: highest purchase price; lower machining efficiency (tool-consuming); worst weldability—weld repair is extremely delicate and can crack if mishandled. |

Runner System Share and Steel Fit: In-Depth Evaluation

| Runner Type | Industry Share | Operating Characteristics | Recommended Steel | Selection Rationale (Core Pain Point Solved) |

|---|---|---|---|---|

| Full Hot Runner (valve gate/open) | Approx. 75% | Local areas remain at 200°C–280°C for long periods; injection pressure acts directly on the cavity. | 1.2311 | Anti-softening and anti-leakage: P20 hardness can drop below 20 HRC at 300°C, causing sealing areas to deform and leak. 1.2311 maintains stable high-temperature hardness to ensure reliable sealing. |

| Semi-Hot Runner (hot tip + cold runner) | Approx. 15% | Heat source concentrated at the gate; significant thermal gradient stress exists inside the mold. | 3Cr2Mo | Fatigue resistance with high value: 3Cr2Mo has good toughness and moderate hardenability, handling thermal cycling stress well—suitable for mid-tier projects of 300,000–500,000 cycles. |

| Conventional Cold Runner (large sprue) | Approx. 10% | Mild environment; overall heating is uniform (about 60°C); no thermal-load requirement for the material. | P20 | Ultimate cost orientation: without localized high-temperature sources, P20’s base performance is sufficient. Fastest machining speed, suitable for small batches or simple-structure sample molds. |

Common Questions for Home Appliance Housing Injection Molds

For large deep-cavity parts such as refrigerator injection housings, which should you choose: P20, 3Cr2Mo, or 1.2311?

Select by production volume tier: Small batch (<50,000 cycles) choose P20 to save cost; medium batch (50,000–150,000 cycles) choose 3Cr2Mo to balance performance; large batch (>150,000 cycles) prioritize 1.2311 to secure service life.

Select by appearance grade: High-gloss mirror products choose 1.2311 due to high cleanliness and strong polishability; general appearance parts choose 3Cr2Mo; lower-requirement structural parts choose P20.

Select by maintenance strategy: If you want long-term stability and fewer repair events, choose 1.2311 or 3Cr2Mo. Their hardness is higher (30–35 HRC) than P20, improving wear resistance and effectively preventing scratch issues caused by deep-cavity demolding over long production runs.

For air-fryer housing injection molds, which is more suitable: P20, 3Cr2Mo, or 1.2311?

Select by volume: Small batch (<300,000 cycles) use P20 for the lowest cost; mid-to-high volume (500,000–1,000,000 cycles) use 3Cr2Mo for the best value; ultra-high volume (>1,000,000 cycles) prioritize 1.2311 to secure mold life.

Select by resin/material: If the plastic contains glass fiber or flame retardants, prioritize 1.2311. Its higher cleanliness and hardness (HRC 32–35) resist high-pressure erosion and acidic gas corrosion, preventing the cavity surface from becoming rough.

Select by finish/process: For high-gloss/mirror finish requirements, choose 1.2311; its polishability (up to Ra 0.02 μm) is far superior to P20. For general appearance parts, 3Cr2Mo is sufficient.

For robot vacuum housings, which should you choose: P20, 3Cr2Mo, or 1.2311?

Select by part type: For the top cover (appearance part), choose 1.2311—high cleanliness, no sand holes after polishing, suitable for high-gloss or mirror finishes. For the chassis (structural part), choose 3Cr2Mo—lower cost with sufficient wear resistance.

Select by material: If the plastic contains glass fiber (GF), prioritize 1.2311 + nitriding. Hardness can be increased to HV800+, preventing cavity roughening caused by glass-fiber erosion and greatly extending mold life.

Select by production volume: <300,000 cycles use P20 (cost saving); 500,000–800,000 cycles use 3Cr2Mo (best value); >1,000,000 cycles or export molds must use 1.2311 (very high stability).

For precision instrument housings, how do you choose among P20, 3Cr2Mo, and 1.2311?

By precision (±0.02 mm): Must choose 1.2311. Its thermal stability is extremely high, preventing micro-deformation during mass production and ensuring tight, gap-free assembly.

By surface (mirror grade): Prioritize 1.2311. Its cleanliness is extremely high; after polishing there are no sand holes or pitting, and it can achieve Ra 0.02 μm mirror finish. For general precision requirements, 3Cr2Mo is sufficient.

By material (glass fiber filled): If the plastic contains glass fiber (GF), choose 1.2311 + nitriding. It resists erosion better than P20 and prevents premature wear that causes dimensional out-of-tolerance.

By positioning (domestic vs export): Export/high-end instruments specify 1.2311 (benchmarked to DIN). China mid-range instruments choose 3Cr2Mo (stable performance, fast lead time, high value).

Conclusion

Mold material selection is not “the more expensive, the better,” but rather “the best match to operating conditions.” Based on real-world performance of P20, 3Cr2Mo, and 1.2311, moldsteells recommends finalizing your decision using the logic below:

| Core Requirement | First Choice | Alternative | Core Reason |

|---|---|---|---|

| High-gloss mirror / precision panels | 1.2311 | Premium P20 | Extremely high cleanliness, no sand holes; clearer and deeper polish |

| Hot runner / glass-fiber & flame-retardant parts | 1.2311 | 3Cr2Mo + nitriding | Strong thermal stability; resists high-temperature softening and erosion |

| Mid-to-high volume structural parts | 3Cr2Mo | P20 | Best value for money; service life far exceeds standard P20 |

| Short trial production / simple molds | P20 | 3Cr2Mo | Lowest initial procurement and machining cost |