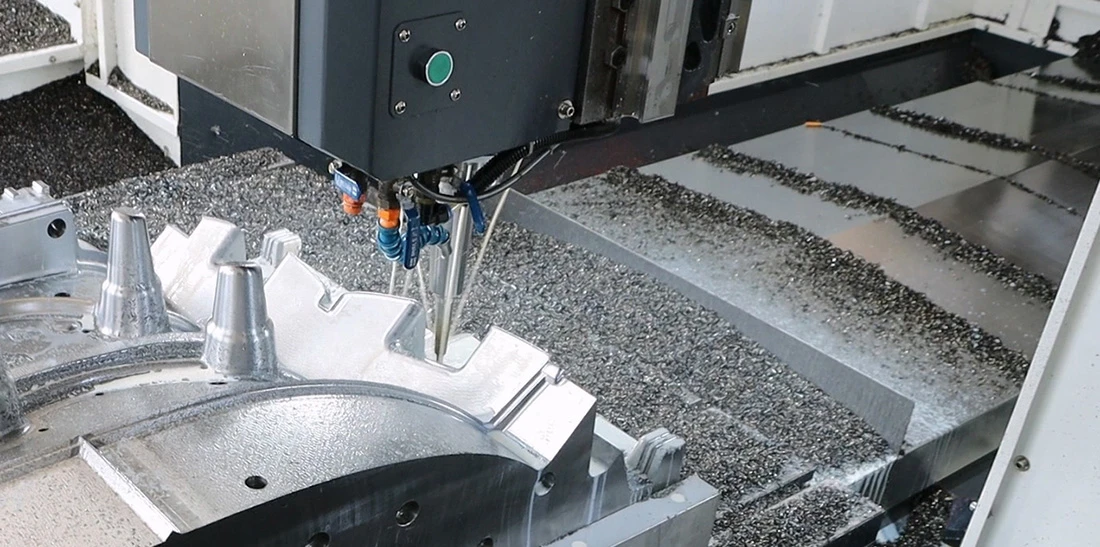

If you are milling plastic mold cores with NAK80 and recently noticed that it’s getting “harder and harder to cut”—with rapid tool wear, frequent edge chipping, and a much longer cycle time (for example, what used to be 1 part per hour now takes 3 hours)—then your labor cost, tooling cost, and rework cost will all rise together. In most cases, this is a classic case of work hardening.

We encountered the same issue. At first, we assumed it was purely a tool problem, but the real bottleneck was the combination of cutting parameters and heat/stress control.

The moldsteells team ultimately broke the solution into three areas: feed, speed, and cooling + tool management.

Step 1: Reduce the Feed Rate (from 0.2 mm/rev to 0.12 mm/rev)

1) Why reducing feed helps solve work hardening

In milling, the higher the feed rate (mm/rev), the more material is removed per revolution, and the higher the load on the cutting edge. For pre-hardened steel such as NAK80, as load and friction increase, the surface layer undergoes significant plastic deformation. This is essentially “compressing and hardening” the metal surface.

Reducing feed from 0.2 to 0.12 means the material removed per revolution becomes:

0.12 ÷ 0.2 = 0.6

That is, the feed is reduced by about 40%, and the edge load drops significantly. With lower feed, instantaneous compressive force, friction contact area, and edge loading all decrease, making the surface less likely to be “work hardened.”

This not only reduces work hardening, but also lowers tool load—therefore extending tool life.

2) Why does the hardened layer become thinner when the feed is reduced?

When the feed is too high, the cutting force increases, and the hardened layer becomes thicker and more continuous. After lowering the feed, the cutting force decreases, so the hardened layer naturally becomes thinner. The next pass can more easily cut through the hardened layer and enter normal base material, breaking the hardening cycle—tool life improves noticeably.

3) Why reducing feed reduces friction and temperature rise

NAK80 pre-hardened steel is susceptible to temperature and friction. If the feed is too high, the cutting edge carries a heavy load, leading to frictional heating and localized high temperature. The surface experiences rapid “hot–cold” changes, making the microstructure less stable, and increasing work hardening and surface damage.

4) After lowering feed, the tool is less likely to chatter, stall, or chip

In corners or narrow slots, the tool can easily “catch” or “shake,” and high feed makes this more likely. Once catching/chatter occurs, the edge stops cutting cleanly and instead repeatedly rubs and compresses the surface—this “kneads” the surface layer into a hardened zone, making work hardening worse. Lower feed reduces catching/chatter, so the surface is less likely to be repeatedly rubbed and hardened.

Step 2: Increase the Cutting Speed

1) Increase cutting speed from 150 m/min to 220 m/min

Raising cutting speed from 150 to 220 m/min can deliver the following benefits—provided you also use a higher-performance tool (such as TiAlN-coated carbide) and match feed/depth of cut with enhanced cooling and chip evacuation:

- Shorter machining time per part (commonly 35–40%)

- Higher productivity (about 40%+)

- Better surface quality (e.g., Ra 1.6 → Ra 0.8)

- Less polishing stock (reduced by about 30%)

As a result, both lead time and total cost can be reduced at the same time.

2) Use TiAlN-coated carbide tools

The key advantage of TiAlN-coated carbide tools is that the coating can maintain high hardness and oxidation resistance at high temperature (up to around 800°C). It also provides a smoother surface and better chemical inertness, which helps reduce friction and prevent built-up edge (BUE)/material adhesion. This supports higher cutting speeds and shallow-cut strategies.

In practice, tool life can improve from “replace every 1 hour” to multiple times longer (commonly 5–7× or even more). At the same time, surface roughness can be reduced to Ra < 0.4, increasing yield and significantly reducing total cost.

Step 3: Strengthen Cooling and Lubrication—Use Oil-Based Cutting Fluid, and Inspect the Cutting Edge Every 10 Minutes

The role of oil-based cutting fluid

For NAK80 mold machining, switching to an oil-based cutting fluid mainly provides stronger lubrication. With extreme-pressure (EP) additives (such as sulfur/chlorine/phosphorus), it forms a protective lubricating film under high temperature and high pressure. This significantly reduces tool–workpiece friction and prevents built-up edge and scratching, while also carrying away heat and improving chip evacuation. The result is better surface finish, less deformation scrap, and a multiple increase in tool life.

Inspect the cutting edge every 10 minutes

The core value of “inspecting the cutting edge every 10 minutes” is short-cycle monitoring of tool wear/edge chipping, preventing a damaged edge from instantly causing surface scratches, dimensional fluctuations, and a surge in polishing allowance. A more efficient approach is to upgrade it into a standardized system: inspection checklist/SOP + tool life tracking, or condition-based monitoring via vibration, cutting force, or visual monitoring. Then adjust inspection intervals dynamically by process criticality (for example, keep 10 minutes for critical features, extend to 15–30 minutes for non-critical areas), ensuring quality while reducing unnecessary downtime.

Stress Relief Tempering After Rough Machining

After rough machining of an NAK80 mold, performing one low-temperature tempering cycle (200°C × 1 hour) is primarily to relieve residual stress generated during roughing and stabilize the microstructure. This helps prevent deformation, dimensional drift, or micro-cracks during subsequent finish machining, EDM, or polishing. Keeping the temperature at around 200°C also helps minimize any impact on the original hardness.