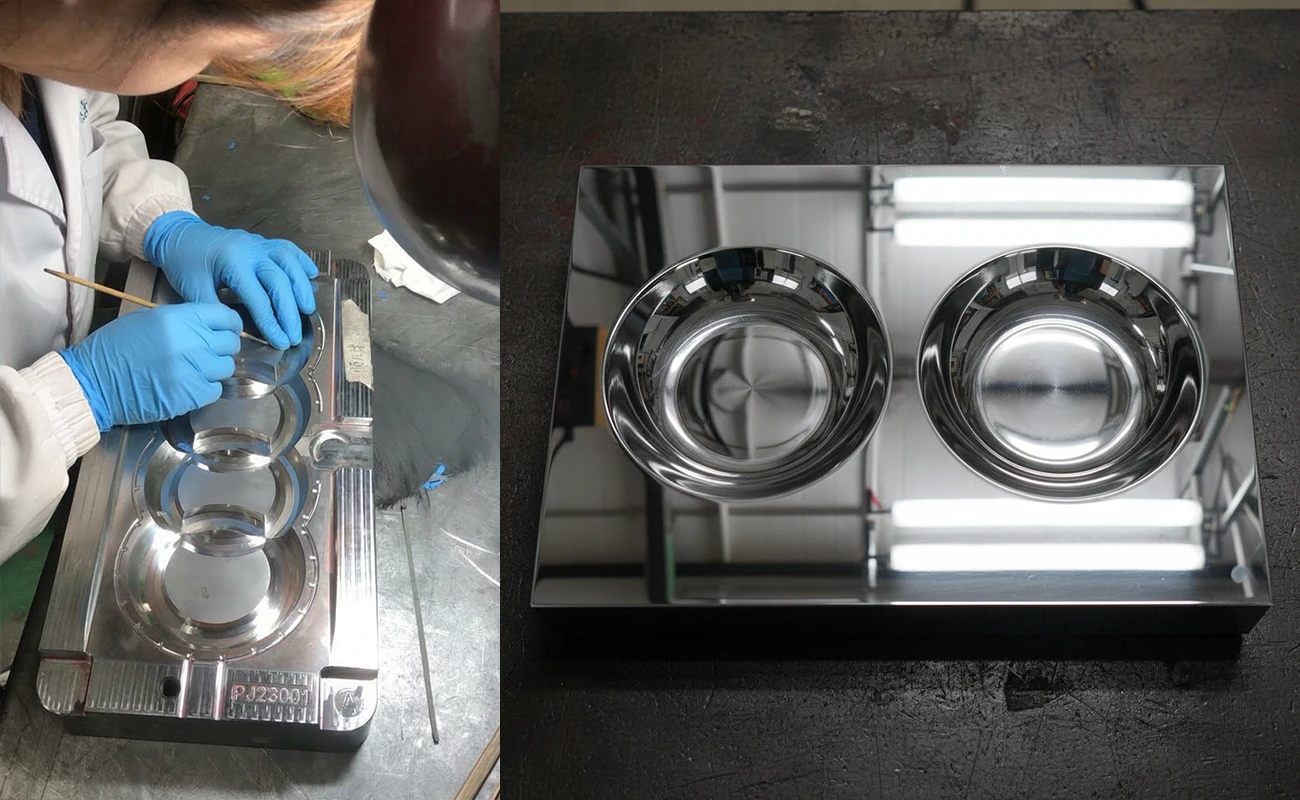

If you are using NAK80 for mirror-finish molds and keep running into this situation—polishing issues where the surface always shows fine scratches, cannot meet the customer’s mirror requirement, switching polishing compounds still doesn’t remove the marks, and sometimes the more you polish the more obvious the lines become—then you are very likely dealing with the same type of root cause we encountered this time.

1) Check Material Pre-Treatment

Step 1: Request the supplier to provide a heat treatment report.

Step 2: We used a three-point hardness inspection method:

- Point 1: Select three test points on different areas of the steel block.

- Point 2: Measure using a Rockwell hardness tester (HR-150A).

- Point 3: Take the average value as the final result.

The results confirmed the factory hardness of this NAK80 batch was 38–42 HRC.

2) Investigate the Polishing Root Cause

- Although NAK80 is a pre-hardened mirror-finish mold steel, its relatively high nickel (Ni) content means that skipping grit steps during polishing can easily produce stress-induced scratches. Meanwhile, CNC machining can indeed introduce residual stress in the mold—especially when you have:

- large material removal

- high tool extrusion force

- obvious localized heating

- high clamping force

- or you go into precision grinding/polishing immediately after machining

After troubleshooting by the Moldsteells team, we confirmed the issue was mainly caused by residual stress. We then sent the part for stress-relief heat treatment.

The selected process was stress-relief annealing at 500 °C × 2 hours—essentially putting the steel part into a furnace to “bake it” so that the internal machining stress can be released.

3) Adjust the Polishing Sequence

We changed the polishing workflow to the following sequence:

- Start with #400 grinding wheel for rough grinding

- Then progressively wet-sand with #800, #1200, and #2000 sandpaper

- Finish with diamond polishing paste (W3.5) using a wool wheel

- Control the rotation speed at 1500–2000 rpm

The final mirror finish met the customer’s requirement at Ra 0.02 μm. The customer was delighted, and this process has been adopted for subsequent mass production without the fine-scratch issue recurring.

Key Notes During Polishing

- Increase sandpaper grit step by step; avoid skipping grits, which can cause persistent scratches.

- Diamond polishing paste (a polishing compound containing diamond micron powder) has high cutting hardness and is suitable for high-hardness mirror polishing of NAK80.