NAK80 mold steel is widely used in medical syringe molds due to its excellent comprehensive performance. Still, its high cost has long been a major challenge for small- and medium-sized mold enterprises handling small-batch orders. When communicating with customers in practice, principals of small factories often mention: “In small and medium-batch orders (below 500,000 mold cycles), the cost of NAK80 material can account for 30-40%, severely squeezing profit margins.” It is noted that the price of NAK80 is three times that of 45# steel, and there is an urgent need for a pre-hardened steel solution with better cost performance. The industry generally has a demand for “NAK80 is a bit expensive for medical syringe molds, are there any steels that can replace it?” At the same time, blind material substitution has led to production accidents: a Chinese mold factory replaced S136 medical-grade stainless steel with ordinary P20 steel to cut prices, resulting in severe wear and corrosion of the mold, unqualified products, and the need to reopen the mold. Therefore, scientifically screening economical and qualified alternative steels has become the focus of the industry. This content is compiled from the practical experience of moldsteells in mold steel customization and processing projects, for industry reference.

Core Requirements for Material Selection of Medical Syringe Molds

Material selection for medical syringe molds needs to meet multiple medical-grade core performance requirements to ensure product safety and mold reliability. In actual production, there have been cases where molds rusted in the cavity after ethylene oxide sterilization due to insufficient corrosion resistance, leading to the scrapping of entire batches of syringes. It is clearly pointed out that the key factors include: 1. Polishing performance (needing to achieve a mirror finish to ensure the inner wall of the syringe is smooth and free of defects, avoiding drug residue); 2. Corrosion resistance (preventing chemical corrosion during drug contact or disinfection processes); 3. Wear resistance (ensuring the mold maintains precision during the production cycle and extends service life). These requirements provide basic standards for screening alternative materials, and any alternative steel must meet the medical application requirements in the above indicators.

Recommended NAK80 Alternative Steels and Performance Comparisons

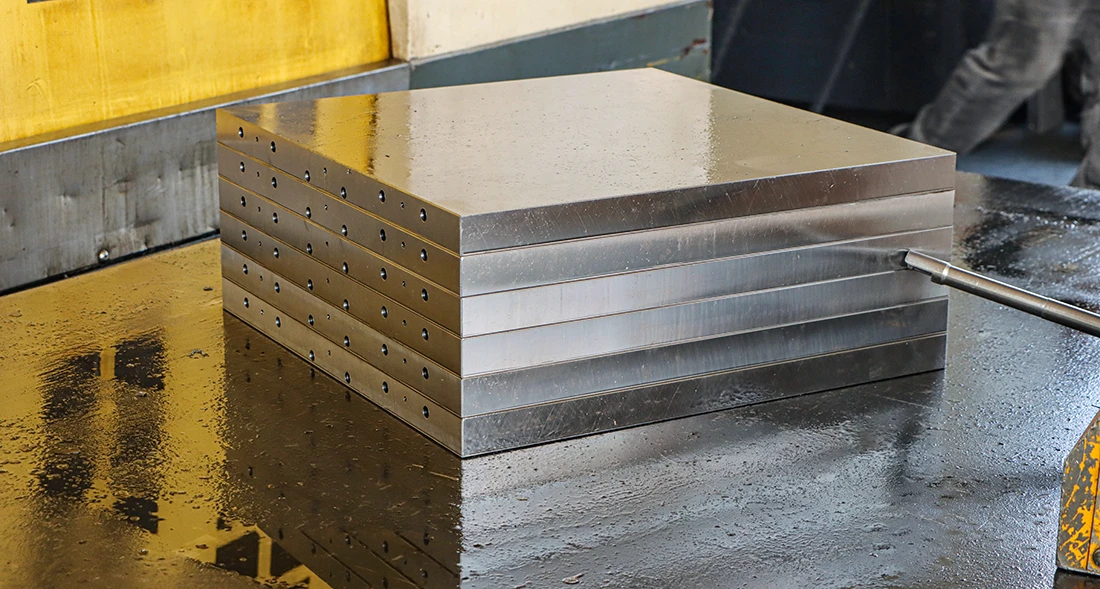

Combined with industry practice and material characteristics, the following 6 types of steel can be used as economical alternatives to NAK80, and their performance and applicable scenarios are compared in Table 1:

| Alternative Steel | Price Comparison (vs NAK80) | Corrosion Resistance | Polishability | Wear Resistance | Applicable Scenarios |

|---|---|---|---|---|---|

| S136H | 15-20% lower | Better than NAK80 (due to 13% Cr content, superior corrosion resistance) | Close to NAK80 | Pre-hardened hardness 30-34HRC (NAK80 is about 38-42HRC, the common pre-hardened hardness range in the industry) | Small and medium-batch production with high surface quality requirements |

| 4Cr13 | About 30-40% lower | Basically meets medical-grade requirements | Slightly inferior, requiring additional post-polishing processes (Ra0.05-0.08μm, NAK80 can reach Ra0.02μm) | Pre-hardened hardness 28-32HRC, moderate wear resistance | Molds for cost-sensitive, non-critical structural parts |

| 718H | About 25% lower | Moderate corrosion resistance, surface treatment is recommended to meet medical disinfection requirements | Good surface quality in 100,000 mold cycle tests (Ra0.04μm) | Pre-hardened hardness 32-36HRC, no obvious wear after 100,000 mold cycles | Medium-batch production with low welding requirements |

| CALMAX 635 | About 30% lower | Moderate (regular maintenance for rust prevention required) | Good (Ra0.03-0.05μm) | Pre-hardened hardness 34-38HRC, wear resistance is close to 85% of NAK80 | General scenarios prioritizing cost performance |

| H13 | Moderate cost (about 10-15% lower) | General (chrome plating on the surface is recommended) | Meets basic mirror finish requirements (Ra0.06-0.09μm) | Hardness 48-52HRC after quenching, service life is about 60% of NAK80 | Small-batch or short-term projects |

| 3Cr13 | About 50% of NAK80’s price | Appropriate surface treatment (such as nitriding) is required to meet requirements | Slightly inferior (Ra0.07-0.10μm) | Pre-hardened hardness 26-30HRC, moderate wear resistance | Molds for non-critical structural accessories |

Notes on Selecting Alternative Materials

When selecting alternative materials, we must guard against the “cost-only theory” and ensure that the basic medical-grade requirements are met. Cases show that ordinary P20 steel leads to rapid mold failure and unqualified products due to insufficient corrosion resistance and polishability, thereby increasing total costs. Therefore, alternative materials must undergo strict verification: it is recommended to elevate steel selection and verification to the highest priority, include them in the SLA (Service Level Agreement), and confirm key indicators through third-party testing. For example, the polishability must meet the Ra0.02 μm mirror standard. The corrosion resistance must pass the neutral salt spray test for 48 hours without rust, to avoid production risks caused by substandard materials.

Other Cost Optimization Suggestions for Small-Batch Orders

In addition to material replacement, small-batch orders can further control costs through process optimization. For example, adopt composite mold design to achieve multi-cavity per mold, improving production efficiency by 30% within 100,000 mold cycles; reuse standardized mold bases (such as Longji standard mold bases) to reduce custom processing time and costs; use rapid prototyping (3D printing) to verify the structure of non-critical cavities, reducing mold opening risks.

Conclusion

Economical alternative steels to NAK80 each have their own focuses: S136H has balanced performance and is suitable for scenarios with high surface quality requirements; 4Cr13 and 3Cr13 have outstanding economic efficiency and are suitable for non-critical structures; 718H and CALMAX 635 have excellent cost performance and are suitable for medium-batch production; H13 is an ideal choice for small-batch or short-term projects. Enterprises need to make comprehensive decisions based on order scale, budget, and performance requirements, and always take material verification as the premise – ensure that alternative materials meet medical-grade standards through third-party testing, while reducing costs and ensuring product quality.

- Priority should be given to pre-hardened steel to reduce the cost of heat treatment links

- For small-batch orders, priority should be given to testing 3Cr13 (cost reduction of more than 40%) or H13 (cost reduction of about 15-20%)

- Third-party testing must include salt spray test (48h) and mirror polishing (Ra0.02μm) verification